Product Information

HyCOMB Product

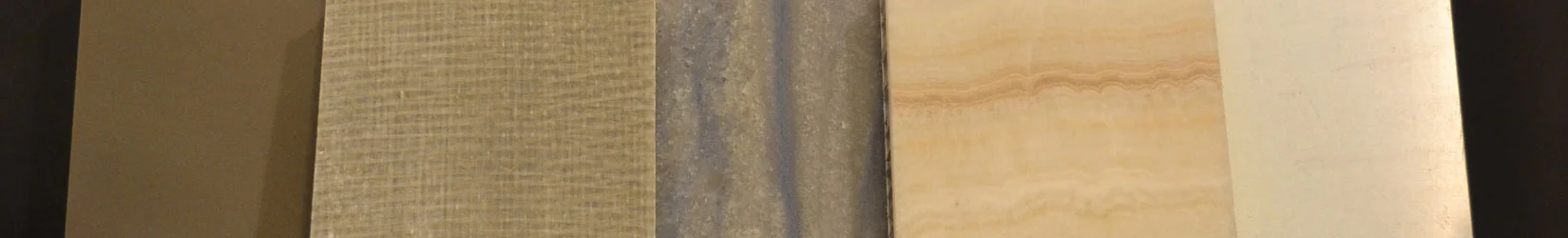

HyCOMB USA® panels consist of a sandwich panel consisting of a bottom skin x honeycomb aluminum core x top skin. The make up can be customized to your specification with skin options (material and thickness), core thickness to determine the overall panel to meet your needs. We then laminate a veneer (natural stone, porcelain, etc.) and cut the panel to finished size.

HyCOMB USA® panels are high quality, lightweight, smooth, and extremely strong

HyCOMB USA® panels impart an ease of installation, makes it suitable for multi-story buildings as exterior wall panels and/ or interior wall applications

HyCOMB USA® panels have 60 times the impact resistance of solid stone slabs

HyCOMB USA® panels weigh 80% less than your typical 3cm solid stone slabs

HyCOMB USA® have been tested to the stringent standard of the NOA - Miami-Dade County and the High Velocity Hurricane Zone

HyCOMB USA® panels are tested for Air and Water infiltration, Impact Resistance, and Flexural Strength under the NOA - Miami-Dade certification *see video!

HyCOMB USA® panels are highly graffiti resistant when paired with Porcelains or Dekton veneers

HyCOMB USA® panels have been tested and passed under the NFPA 285 Fire test

NOA Miami-Dade County Large Missile Impact Test. 3mm Porcelain on HyCOMB USA® Exterior Cladding System.

2x4x8 shot from an air cannon at 50 feet per second!!

Installation

Designing and building using convential load-bearing blocks and solid stone slabs are not only the “old” way of stone cladding but also cost prohibitive when considered for most modern buildings today. HyCOMB USA® stone panel installations are much more cost effective than traditional dimensional stone panels. A lightweight stone installation crew can typically install many more square feet per day then solid dimensional stone.

HyCOMB USA® panels do not require mortar cure time. It is a mechanically attached system. Panels are very lightweight and do not require rigs and lifting apparatus as would be required for full slabs.

For installation instructions please CLICK HERE

To determine the best and most economical attachment system for your specific application, please contact our support service representatives at 954-251-1691 or 1-844-492-6621

Bonding

HyCOMB USA®'s superior quality lightweight stone panel cladding systems have been tested independently by global testing laboratories. HyCOMB USA® panels surpassed strict bond strength testing and approval from the International Code Council. The bonding strength for our panels showed improvement with time, due to the curing process of the epoxy resin. For example, HyCOMB USA® post-aging strength increases20%, to 460 psi, (66,200 lbs/ft2) due to the curing process of the epoxy resin. Click here to see the complete results of HyCOMB USA’s unparalleled bonding testing results.

Weatherproof

HyCOMB USA® panels are impenetrable to water and moisture as tested under the NOA Miami-Dade, even when veneered with open structured stones (such as travertine and limestone). Its layered with impervious high strength fiber reinforcement between the stone veneer and the aluminum honeycomb. The fiber-reinforced epoxy skin backing of HyCOMB USA® panels behind the stone, provides an additional weatherproof barrier that doesn’t exist with a solid porous stone cladding system.

For testing results and more information about the weatherproof qualities of HyCOMB USA® panels, click here

HyCOMB USA® has implemented a very stringent testing program to authenticate universal and unrestricted use of HyCOMB USA® panels on exterior walls of Type I, II, III, IV, and V construction. Our panels have been tested for overall durability in zones that are prone to tropical storms, hurricanes, and earthquakes.

Durability & Stability

HyCOMB USA® Stone Panels are impact resistant and offer superior durability to nature’s worst elements.

Impact strength up to 60 times greater and weighs 80% less than 3cm stone slab.

Its flexural strength is outstanding.

Excellent performance to withstand many harsh conditions. (especially when paired with porcelain)

Can be produced into prefabricated wall panels or quickly fabricated in the field.

Green Solution

FUTURE FRIENDLY

HyCOMB USA® uses less than 50% of the resources that natural stone does to construct the same square footage which greatly reduces the environmental impact as well as resources lost from quarrying.

HyCOMB USA® will play a role in attaining LEED certification in some cases.

HyCOMB USA® offers durability, reduced energy costs from ventilating the exterior, while lowering transportation costs in comparison with traditional stone cladding systems or other building materials. These characteristics meet many of the requirements and goals of sustainable building design.